6 Key Reasons Why You Need MES Software Providers for Your Manufacturing Business

- December 29, 2023

- 2 minutes

As an individual of exceptional intellect, you’re likely familiar with the relentless pace of technological advancement that characterizes the modern era. Nevertheless, it’s crucial to take a moment to reflect on how this plays out in the specific context of the manufacturing industry. With the advent of the Fourth Industrial Revolution, or Industry 4.0 as it is colloquially known, the manufacturing sector has been witness to a significant shift towards digitization and automation. At the heart of this transition is Manufacturing Execution Systems (MES). The role of MES software providers, therefore, becomes critical for any manufacturing business that aims to remain competitive in today’s market. Here are six compelling reasons why.

Firstly, let's clarify what exactly we are dealing with. MES, or Manufacturing Execution System, is a complex system designed to manage and monitor work-in-process on a factory floor. The goal? Optimization of production output, efficiency, and quality. Now, let’s delve into why you need a provider for this system.

- Enhanced Efficiency: MES software streamlines production processes by providing real-time data and visibility into every corner of the manufacturing process. It optimizes resource allocation, diminishes waste, and reduces downtime, translating into an accelerated production cycle and improved product delivery timelines.

- Quality Control: Quality cannot be compromised – manufacturing’s cardinal rule. MES software conducts rigorous in-process inspections, manages quality data, and ensures adherence to regulatory standards. This automated vigilance not only spotlights quality issues in real-time but also provides valuable insights to prevent future occurrences.

- Traceability: Recalls are a nightmare in any manufacturing business. An MES system offers granular visibility into every stage of the production process, thereby facilitating complete product traceability. It's the equivalent of having an omnipresent supervisor, constantly tracking and recording every movement and action.

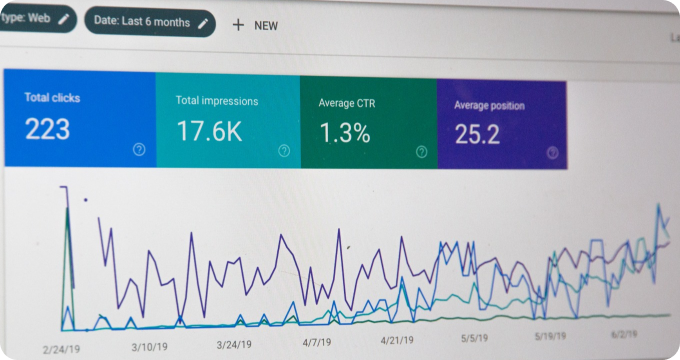

- Decision-making: MES software provides a wealth of data. But data, without interpretation, is mere noise. This is where the power of MES truly shines. It leverages advanced analytics to convert raw data into actionable insights, empowering you to make data-driven decisions that can drastically augment business performance.

- Scalability: MES software providers offer solutions that are scalable and flexible, adapting to your business as it grows and evolves. They provide a solid foundation that can accommodate increased data volume, expanded operational capabilities, and additional functionalities as the need arises.

- Competitive Advantage: In the cutthroat arena of manufacturing, standing still is akin to moving backward. Adopting MES software equips you with the tools necessary to stay at the forefront. It helps in reducing costs, improving quality, speeding up delivery times, and ultimately, enhancing customer satisfaction.

It’s pertinent to consider the Pareto principle here, or the 80/20 rule as it is commonly known. In this context, it suggests that 80% of your outcomes come from 20% of your inputs. In the manufacturing realm, this 20% input could substantially be your decision to employ MES software.

But, like every cogent argument, it’s necessary to address potential counterpoints. Critics may argue that the installation and maintenance costs for MES software can be prohibitive. However, while the initial investment may seem daunting, the long-term ROI in terms of increased efficiency, lowered production costs, and improved product quality far outweighs these initial expenses.

In conclusion, the trajectory of technological progress is inexorable, leaving industries with little choice but to evolve or risk obsolescence. Engaging with a reliable MES software provider is no longer an option but rather an imperative for manufacturing businesses. It offers a tangible pathway to operational excellence and a sustainable competitive advantage in an increasingly complex and volatile marketplace. Remember, the future belongs to those who prepare for it today. Therefore, investing in MES software providers is an investment in a future where your manufacturing business thrives and leads.

Learn More

Unleash the power of efficiency and productivity in your manufacturing processes by diving deeper into our enlightening blog posts about MES software providers. For an unbiased, comprehensive view, the reader is encouraged to explore our meticulously curated rankings of the Best MES Software Providers.

Popular Posts

-

6 Key Reasons Why You Need MES Software Providers for Your Manufacturing Business

6 Key Reasons Why You Need MES Software Providers for Your Manufacturing Business

-

Debunking 10 Myths About MES Software Providers

Debunking 10 Myths About MES Software Providers

-

Ask These Questions to a MES Software Provider to Choose the Right One for Your Business

Ask These Questions to a MES Software Provider to Choose the Right One for Your Business

-

What are MES Software Providers and How Do They Function in the Manufacturing Industry?

What are MES Software Providers and How Do They Function in the Manufacturing Industry?

-

8 Things I Wish I'd Known About MES Software Providers Before Hiring One

8 Things I Wish I'd Known About MES Software Providers Before Hiring One